The forum thread dump continues

Early April 2016

I got the new radiator, lightened my wallet not inconsiderably, and fitted it in a giddy rush. (Hence the little mark in the glorious blackness of radiator enamel. sigh)

Only one small leak when all filled up, and that was a hose-clamp that was slightly loose. Brought up to temperature, and turned around, with no major drama; though it was a little bit of a struggle, having to do a loop around the cherry-picker someone parked next to it.

Mirrors might be a good thing to fix next; but at least now she's fully mobile, so I can also run her up to the workshop to start on the rust & bodywork repairs. The underside of the cab floor on the passenger's side is worse than I first thought; but there's enough solid metal there that I'm not having to do a full reconstruction.

Oh boy how wrong I was on that, looking back. There is a lot of reconstruction to do. And I've gotten very little of it done since then.

Anyway, my next mission was starting on stopping; a project in and of itself that wouldn't be anywhere near complete until early June of this year

So, I started by ~~yanking~~ carefully removing the master cylinder & brake booster.

Not the prettiest thing in the world. And nor does it look anything like what the manual says the truck is supposed to have, which is always an experience.

Hm.

Here, while I ponder the brake system, have some air-conditioning.

The teardown of the brake system continued...

It exposed some unpleasantness.

I've pulled the brake servo and master cylinder apart... well, the master cylinder off the servo, and dismangled the servo. Rusty brake fluid puked out of back of the master cylinder, so the seals are clearly well and truly shot. m/c was set aside for now while I focussed on the servo.

To start with, the linkage to the brake pedal was just flopping about uselessly, and the rod to push on the back of the master cylinder wasn't going anywhere in a hurry; so I pulled off the cylindrical bit on the front, that runs parallel to the master cylinder.

Caution: It contains a spring-a-mathing, and it sprung-a-mathung, even though I was expecting it and was bracing. I did manage to keep hold of all the pieces, though.

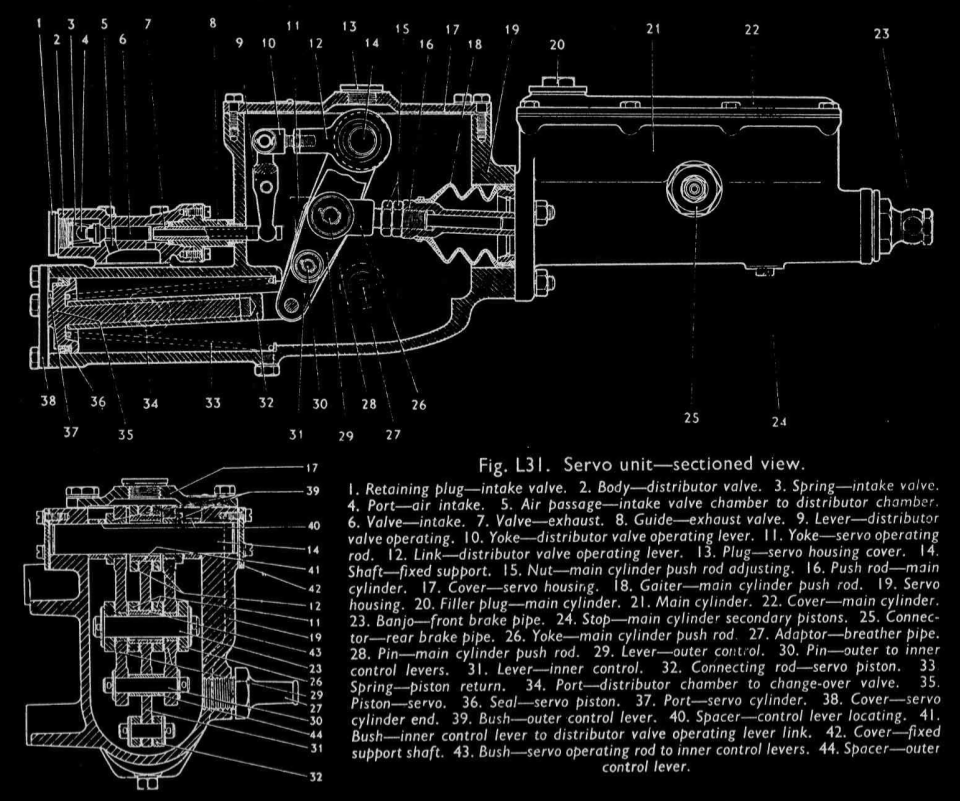

Some cleaning and tinkering ensued, and I did make the air-assist cylinder do its thing, using an air-line. The inside of the servo has sorta the same beam arrangement as the one in the drawing, it's just ...well, completely different. :D

Further disassembly continued at the master cylinder, where this whole sub-project got frustrating and expensive again, but I wouldn't know it at the time.

So, faced with a master cylinder full of stinking oil that bore no resemblance to the brake fluid that should be in there, and expecting it to get worse as I dug in, I did what any reasonable person would do; and ...stuffed it under the bench to deal with later, and built myself a new battery-box to replace the very rotten one.

Cometh the Sunday, after work, and I go to fit it. The big yeller beastie is driven into the workshop, and the weldening ensues.

It's less good when you realise that the only thing holding it on, at that point, was literally just a set of plug welds in the side, through to the cab frame; because there was nothing to weld onto, at the other side. :D But it's better than the original one was, because that disintegrated completely as I stopped the truck after getting into the workshop, and dropped the battery out of the bottom of the cab. Nice!

The comedy didn't end there, that evening, though, oh no...

It's not fully welded in as much as I'd like it to be, but it's solid enough that it holds the battery up; and it will do the job sufficiently until I can rebuild the rotten floor around it and it becomes fully welded in. I would've liked to have fixed more of it; but I was already at the workshop until 1900H, and didn't have much light remaining... and didn't want to leave my big yellow hulk blocking the doorway when everyone turned up in the morning. That'd get me one hell of an earbashing.

(Especially since they'd not be able to move it... 😇 They'd have to figure out how to power up the fuel pump and the ignition coil, then figure out where the starter switch is, then figure out they'd need to bridge that with something because the switch doesn't work any more... then they'd have had to drive the whole heavy thing with no brakes all the way back to the compound, whereupon they would've run out of fuel exactly where I did, blocking the gateway into the compound.

It didn't want to start again -- in hindsight, because the pump was struggling to pick fuel up from a pretty much empty jerry-can (And, to be fair, the (full-current!) starter switch was sticking and not working anyway)...

It only got worse from there, too. And my biggest regret is that I didn't have a video camera to capture the whole fox-show. So, I grabbed the forklift to go push the now-dead truck; and managed to drop one of its rear wheels into a pothole deep enough to lift the front -- powered -- wheel off the ground. Did you know that forklifts generally have open diffs? I'll let you imagine how that went!

So my mate had to push 8 tons of forklift up and out of the pothole, using his little Escort van. And then, when the forklift was free, I carefully shoved the truck back -- with him driving -- until it was parked where it should be.