So, after I quit my job...

Well, I ended up driving tipper wagons, and welding gates, on a farm, for two weeks before the network of people (who know people who know people) got me another job; I'm now something akin to a junior truck mechanic at a recovery firm. More hours, more tired, but hey.

Anyway! Since quitting the week leading up to Christmas, here's a run-down of what happened on the truck, bearing in mind, throughout this, that my ex-employer was supposed to be out of that yard by Christmas. Then by the end of January, ...

February 2019

The number of trucks in the yard finally reduced enough that there was a slight clear path from where the Bedford has been sitting for two or so years, that I thought I'd take advantage and scoot to somewhere with fewer puddles.

Careful, careful, past the dead van...

Late March 2019

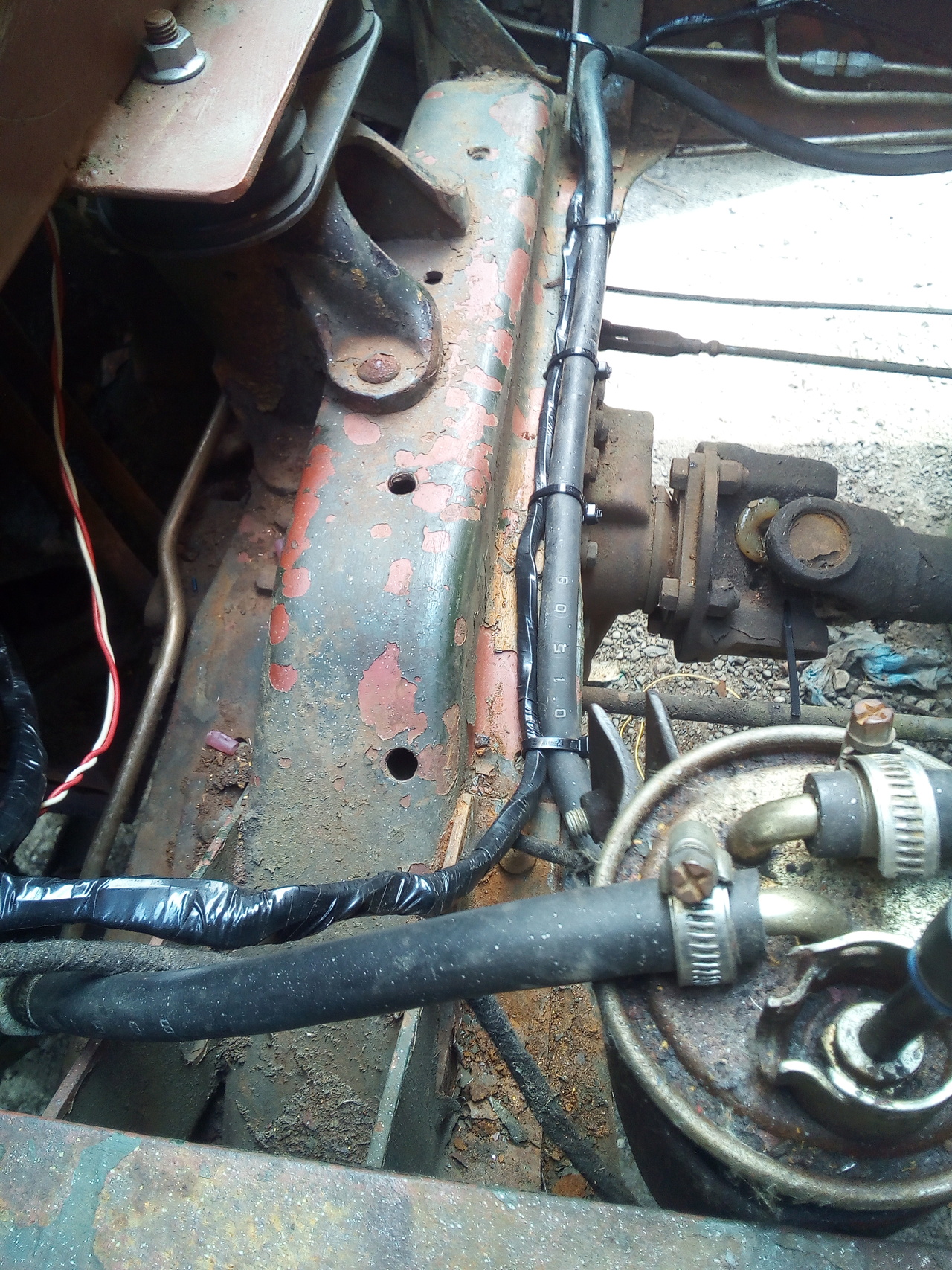

Taking advantage of higher energy than usual, and a couple of dry weekends, I did battle with the brake pipes.

Let's get that back axle piping sorted out, shall we?

Begone with those ugly joined bits that sorta only half-assed followed the factory pipes...

Much better.

The next weekend saw another major milestone achieved...

Yes, that's right; your eyes do not deceive you, there's a pipe! Connected to the master cylinder! But wait! There's more!

Early April 2019

What's this? Brake shoes going back on?

...oh, yeah. Hub has to come off to do these.

Phew, back together. About 45 minutes total, from 'cold', since I'd not touched them in a couple of years.

Well, except for these heavy fucking things...

Phew...

While I'm here, is there anything else I can do that is easy enough to do from laying down in the shade under the truck? hmm...

Let's check that front axle level... Could do with being topped up!

Wonder what the hubs are like; bet this one's a bit low. Pity it's the one with the level plug tightened by the freaking Hulk.

Really needs cleaning off, and those new seals fitting. But I am hesitant to start any work that leaves the truck completely immobile for any longer than a few hours.

Let's run it for a bit, while we're here! ...and find there's an oil leak.

Rocker cover just wasn't sealed, and apparently I'd not run it long enough -- until that point -- for enough oil to get pumped up to the rockers to start dribbling out from under the rocker cover.

Early June

The brake struggles continue...

The rest of my struggling with the brakes, from the day after -- when most of the visible work got done -- didn't end up in that video, because my editor was becoming clumsy and struggling with the footage I'd already loaded into it. Maybe the rest of it will end up in a part 2. Maybe.

Anyway, more brake stuff happened! More specifically, I fit those two front brake cylinders, plumb them up, and get the system properly filled with brake fluid. I also sorta bled it, but managed to destroy my cheapie vacuum bleeder by having the little fluid-trap pot end up upside down, and the pump pulled fluid in, which just wrecked the O-rings.

I also refitted the brake shoes on the nearside, as well, so that the cylinders have some resistance to push against .All those shoes will have to cmoe back off again at some point, either to be cleaned up (where they're of adequate thickness and not contaminated) or to be re-lined. At that point I'll properly clean and check the drums to see if any of them need resurfacing and how close they are to end-of-life spec.

For now, thoug,h there's a hint of braking if I pump the brakes a lot, which is a good sign. I just need to get more fluid, and either a helper or another (better) vacuum bleeder.

Early July

July turned into electricals month, it seems. Nothing really major, though.

How about some work lamps?

More importantly, how about an isolator switch?

The isolator switch install isn't 100% complete, because I need to relocate the alternator's B+ feed to the battery side of the switch, so that flipping the switch cuts off all power to everything even when the engine is running; at the moment, the alternator can keep feeding everything, which isn't ideal. Making the change isn't a big job, I just haven't gotten the supplies ordered yet.

Anyway, at this point, I should note that thing about my ex-work having to be out of that yard by January? Well, by this point, the housing developers are getting a bit miffed at all the stuff still piled up around the industrial estate -- including stuff like truck-mounted equipment that was dumped near the original building they were working at -- and have started condensing the stockpile of shit into that one yard.

I got to the yard and found that there's a truck-body blocking the Bedford's escape route... Uhoh.

And on top of that, I'm being hunted by dinosaurs!

Some weekend work saw more tidying & fixups done to the wiring loom. Stuff like re-running wires that were run in a stupid way originally, now that I know better.

And then a jailbreak happened...

I really do regret not having put my video camera on charge the night before, like I'd considered doing. (But I thought "Ah, nah, I charged it after the last time I used it.", which turned out to be wrong. I'd used it for the brake videos, then dumped it on my desk and not touched it since. The memory card was full, and the battery was empty. d'oh!)

Put it in gear, crawled on up to the box, and thoroughly shoved it out of the way with the front tow-bar. Turns out, also, that if I try to use the bumper for that, it pushes in and the driver's side wheel arch bulges out as everything squooshes. So, on the tow-bar it is. Must fix & perhaps strengthen that bumper, too...

Wherein the truck fled to a different car-park.

And it turns out it's not massively bigger than a Range Rover!

I managed to make the wiper motor twitch a bit while I was playing with wiring, and went to investigate the linkage. One of the wiper spindles is seized up, and the other one turns out to have a bound up and twisted linkage. Unfortunately, I found out about the bound up linkage after I'd disconnected the link bar from the seized up spindle, and the next attempt to move the wiper motor pulled the other spindle out of the rusted roof metal. Argh.

Ah well, it needed fixing anyway, right? 😁 Currently in two minds about those spindles, and need to do a little measuring before I decide what route to go. Either way, the roof has to be repaired to be able to take the loads that the wipers will impose, so that needs to be done no matter what; but whether I repair the spindles, or re-engineer something similar but from a different vehicle/manufacturer, depends on how easy it is to get appropriate-sized wiper arms and whatnot.

But the wiper motor still works, which is nice. Just have to do a minor repair where the mounting screw for the cover is snapped off in the stalk for the switch, and it should be perfectly serviceable. It's the little things, yanno? 🙂

Dragged some other photos off my camera, since I got a sufficiently circular tuit for that:

The Path to Freedom

In profile, compared to a Range Rover or 3

Looming Large