29 Nov 2019

Today's progress on the Bedford was messy (The underside of the pistons filled up with oil, from having the engine sat upside down.) but interesting.

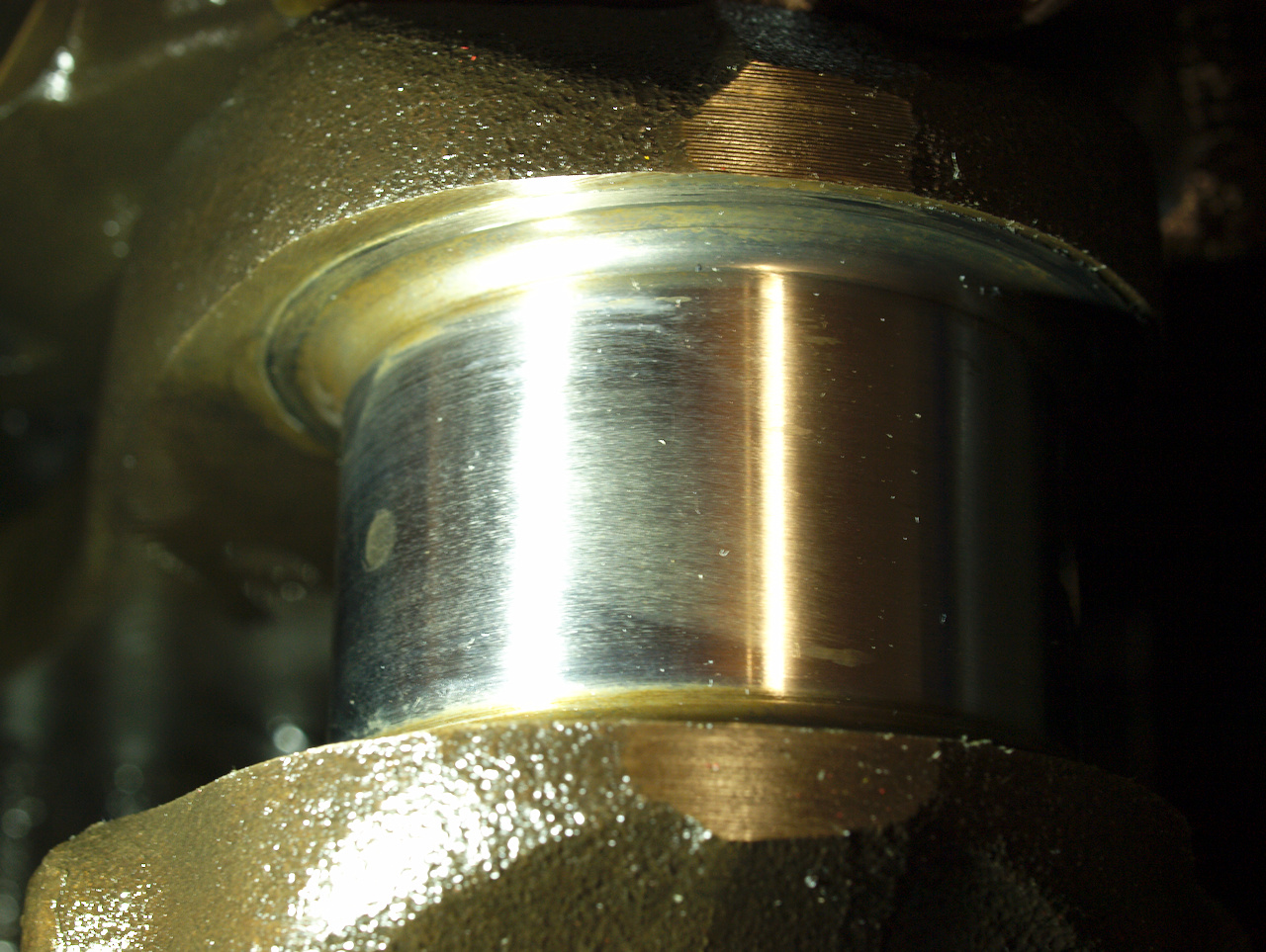

Rod bearings look absolutely brand new:

Rod journals look great, too:

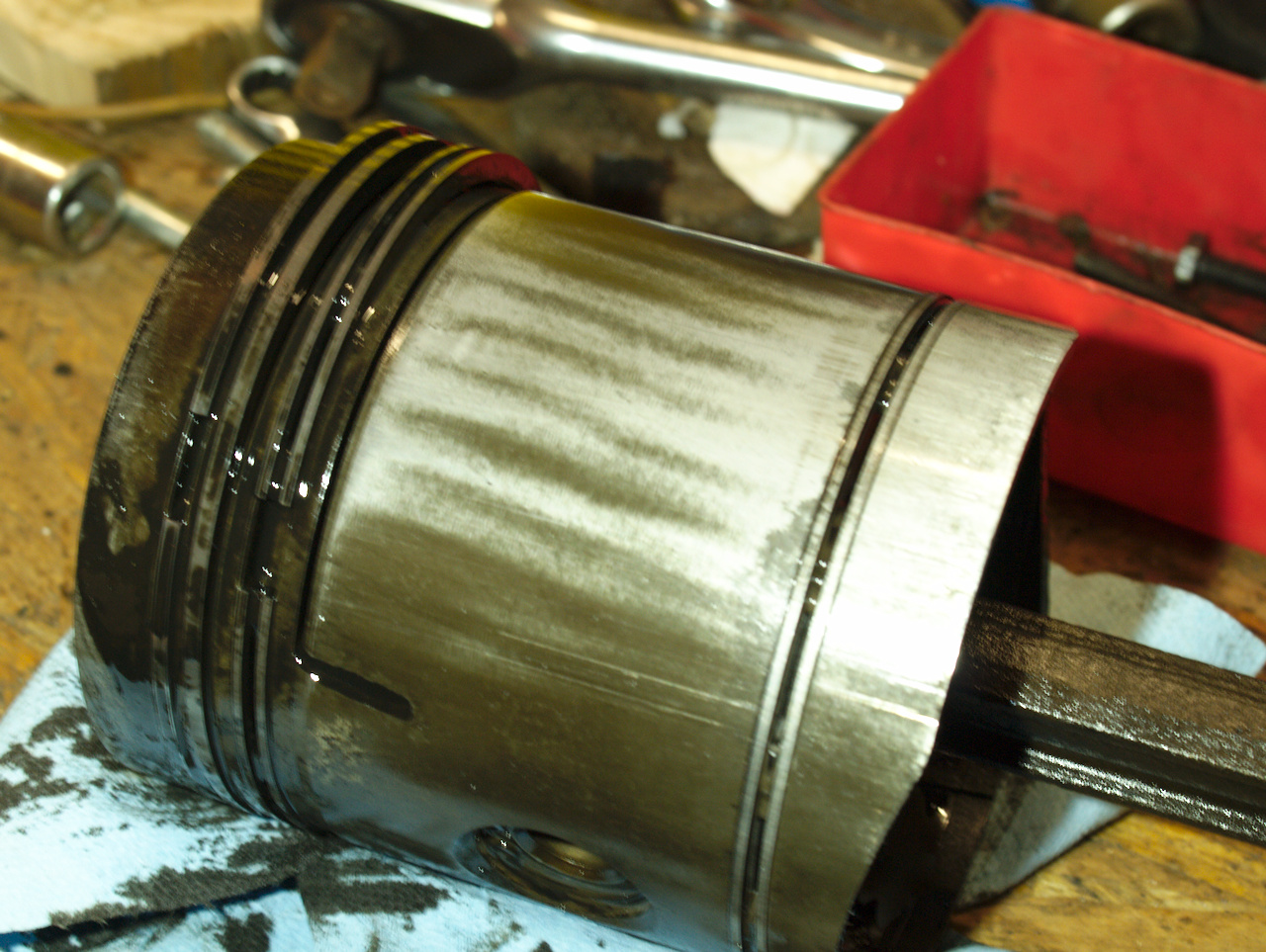

Some unusual pistons. There are two types of piston in this engine, one type stamped 'B' in the crown, the other stamped 'Y' and looks pretty snazzy:

For some reason, I struggled to get a decent picture of the pistons at all; this one has a torch shining up under the piston skirt, to show the interesting cuts and whatnot. The 'B' type piston has fewer cuts/slots in the skirt, and (I think) a heavier skirt overall. I'll try and get better pictures after I've given them a proper cleaning.

Also, unsurprisingly, there were a few stuck rings.

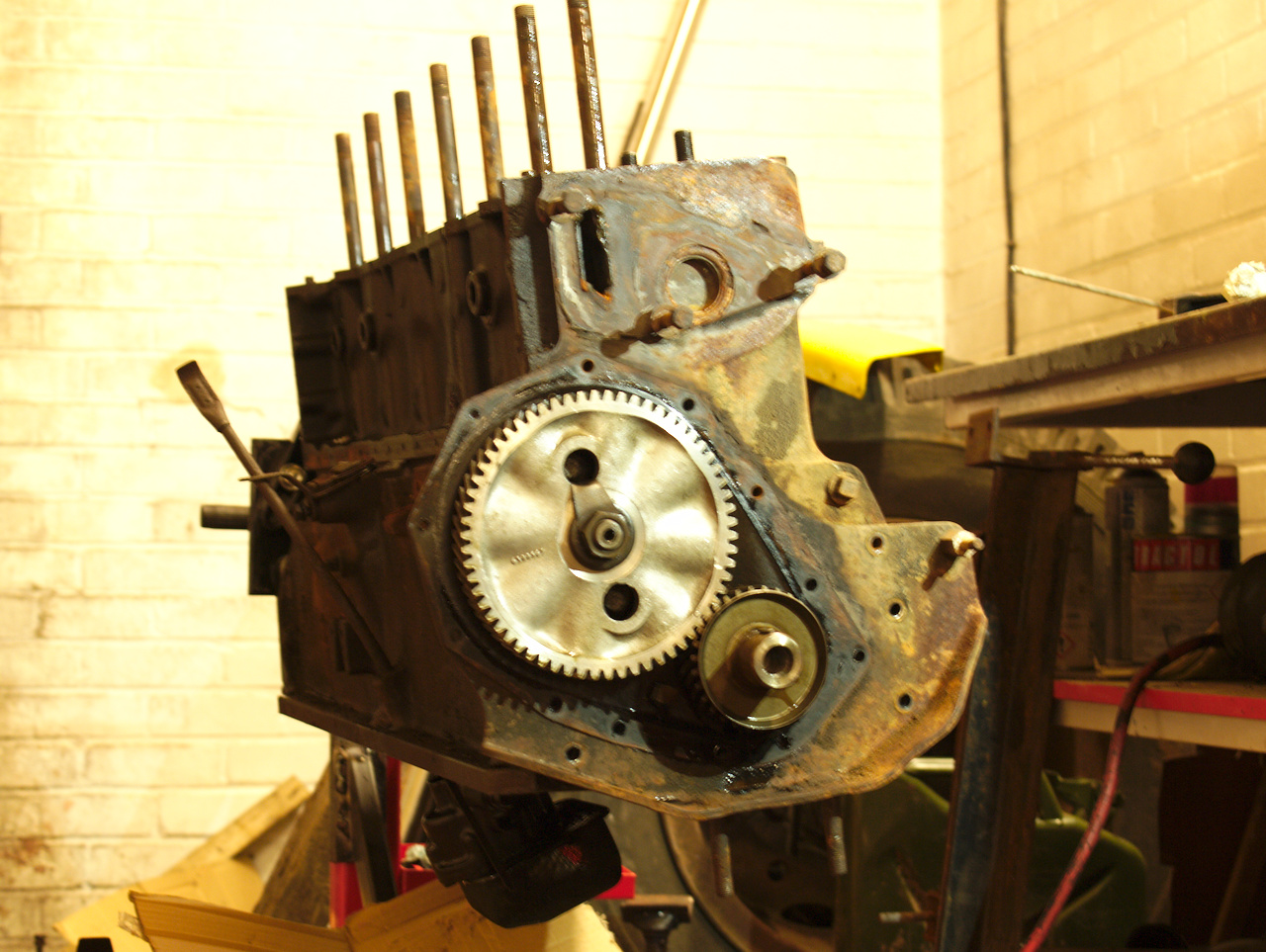

And to end the evening, before I packed everything up:

None of this silly timing chain or belt nonsense going on here! Currently pondering where I might be able to put a cam sensor for the upcoming fuel injection fun and games, and thinking back of the timing case. Just got to see if there's a feature on the back of the cam gear that I can pick up off.

I'm going to need a sensor on the front pulley (current idea is to have a stp machined on a part of the pulley just away from the belt and have a 60-2 ring machined to fit on said step, so it runs true) anyway, but figured if I@m going to the trouble I might as well do the work now to add in cam-angle rather than deciding I want it latre and having to take things back apart.

Also, a picture of the worst cylinder bore of the six:

And the 'B' type piston:

Sweetpea said: So you've got 2 types of pistons in it. That can't be normal is it? Must have been rebuilt with bits they had laying around at some point.

That'd be my guess. And with it having the wrong oil-pan for the 4x4 truck, I'm gonna guess thye blew up the motor it came with, and built up another one with pieces they had laying around. Might explain why it's seemingly a fairly late block (by the engine number) but an early head. (Note from the future: I was wrong thinking this was an early head, basing that on the casting number. The early heads do not fit the late blocks.)

Perhaps they blew it up properly, leg out of bed and all, and scrapped the block & oil-pan.

In actual progress news items, I welded in some angle into the back of the cab so now the removable panel that holds the gear lever gaiters has something to attach to! Next bit that needs attention there is finishing up welding the back of the cab to the cross-member, and putting in the plates on the inside that I couldn't get to previously.

After that, I have a little more sheet metal trimming to do, to finish cleaning up the rear of the cab for a nice shiny new section to go in. Just got to pay attention to my order of operations, don't want to weld in a piece that then gets in the way of other bits.

gtviva said: I should think you have some genuine pistons and some aftermarket. The slots in the skirt let you have a much tighter piston in the bore to stop piston slap and the extra bottom ring was used to reduce oil consumption, most of the engines from the 50s/60s used that style.

Learning new things every day!

Anyway, on the fuel injection front, I've got my mind set on building

a manifold, mostly for the sake of doing it; and I've got a

throttle-body that I'm going to try (It's a bit bigger than the stock

carb, at 52mm compared to the nominal 48mm of the 48VIR. Smoe lazy

searching shows that should be enough for 21m

And, honestly, the factory Bedford manifold is adequate for the 50s, but it really needs the heating from the exhaust manifold hot-spot or fuel puddles under the carb and then trickles down into cylinders 3&4. Not ideal. It'd probably be fine for just moving air, if I wanted to weld injector bungs into it, but I don't really want to hack it up like that.

(Note from the future: Turns out the aluminium of the intake manifold is so old, that the oxide layer penetrates deep enough to make it nigh unweldable.)

Either way, I've already got an ECU (TunerStudio compatible, I think it's an MS2X equivalent) that's set up for 3 injectors and 6 ignition coils. I've got the throttle body (Off an MG TF, I think!). Haven't yet gotten the injectors but I've got it written down somewhere what size and connector type I'm after, got a list of sensors to get and fit, so on and so forth.

I'm aiming for turn the key, hit the button, and have it start just like a modern motor.