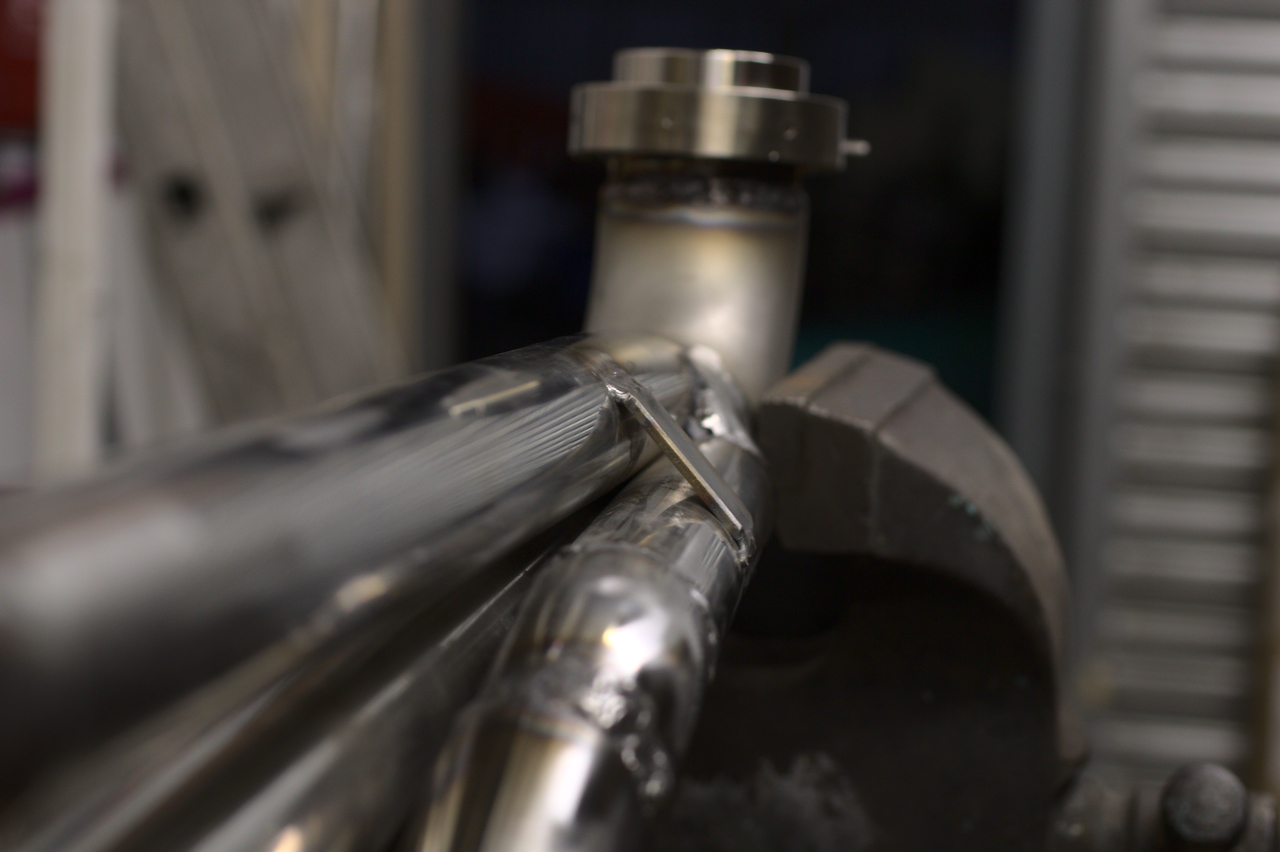

Pretty? No. Getting better at it, though! Managed to spend two evenings after work not in crippling pain, so welded 'til past 10pm...

The 3-to-1 merge didn't go like I planned, I thought I had it figured out but apparently not. Ended up having to slice, heat, beat, and weld my way out. But at least it went better? less bad? than the first one.

There's a bit of twist in it yet, and there's a specific order it has to be bolted up in order to pull it into place properly, but I will see whether the heat of running the engine relaxes that a bit. (It probably won't, and I'll have to break out the gas & oxy to stress relieve a few welds)

Spent some time polishing the most visible bits of it up, too. Nice! Next step will be getting the marman clamp on the other header, then I have the freedom to start it up without potentially contaminating surfaces I need to weld, followed by the unequal 2-1 that merges both headers into one exhaust.

Still no closer to having a coherent design for the inlet manifold, though I did get to confirm that I absolutely made the right decision by deciding I don't want to try and weld injector bungs into the original manifold. Went to braze in some leftovers of the aluminium pipe into the ports, to replace the horrible little steel alignment rings that always fell out while trying to jiggle the manifold into place; and it would. not. braze.

No matter how much I cleaned it, scraped it, scrubbed it, fluxed it, changed gas settings... it would not braze. I could get the rod to wet just fine to the new aluminium tube, but it rolled right off the old manifold like water. I eventually settled for chemical metal, seeing as I had a lump of that left sitting around. Some gaskets on it, and it'll do for testing.

Several Days Later...

There has been a tremendous cock-up with the exhaust headers. I'm very disappointed in all of you!

...

...

...how come nobody reminded me that there's a bloody great front diff I need to make those pipes fit past?!

Current clearance is: Negative a lot.

Frustrating, but not the end of the world, there's plenty of space, it's just in different places than where I put the pipes originally.

I am pretty confident I can cut n shut n weave my way through the available space, but I have learnt a very good lesson here and I am not going to make any more changes to the exhaust until I can sit the engine in the truck, and then know what needs to go where and what clearance it has.

Looks like I'll get a chance to revisit those merge collectors after-all! But the headers are going to stay in their lovely long-tube form at least for a while yet, I want to have the engine running before I go to reinstall it. Easier to fix leaks that way.

In other items, once I stopped sulking from discovering that, I've gone and dug the spigot bearing out to get a replacement, and I've gotten in touch with the good folks at Powerlite about a gear-reduction starter.

Not the cheapest, but does have the advantage of being an improvement over the original, and also I can order it online rather than try and find a window in my perma-death schedule to drop the original starter in with a rebuilder for them to make that horrible tooth-sucking sound and pronounce "that's foxed, mate". Also, they have them on the shelf.

It's an RAC402A, for anyone interested. Fits Aston Martins from 1948 to 1972, and also through the wonders of everybody using the exact same parts-bin (Thanks, Lucas!), a Bedford RL.

Also, the spigot bearing appears to be the ubiquitous skateboard-wheel 6202 (albeit a quality SKF one), which I find highly amusing.

(...and yes, I have been sulking about the header cock-up for about 2 weeks.)

Sweetpea

Mate, just move the axle, it'll be a piece of cake for a chap like you.

Casually flipping the axles upside down, and adding a reverser box in

the middle of the driveline to make up for it, so I don't have to cut

my nice(ish) headers about! Genius!

And I'm not going 2WD. How am I supposed to do 4WD burnouts without it?!

Frankenhealey

No no no no no! Having had a slight problem with the air-assisted Cummins clutch this exact situation occurred and the transmission wind-up can be spectacular.

It's the classic black hole gravity well conundrum translated to old British Army trucks.

With the length of the propshafts and any play in the transfer box it seems that the rear wheels or front wheels can be in motion before the front wheels or rear wheels have finished having a smoke.

Then whichever wheels they are need to catch up, quickly. Depending on tyres and road/field surface that gives rise to an extremely disconcerting motion which is not quite bucking bronco but something that 4 tons of old truck should not be doing.

The only saving grace is that as 4WD is automatically low range it's unlikely to get away from you.

Please post a video if you try. :D