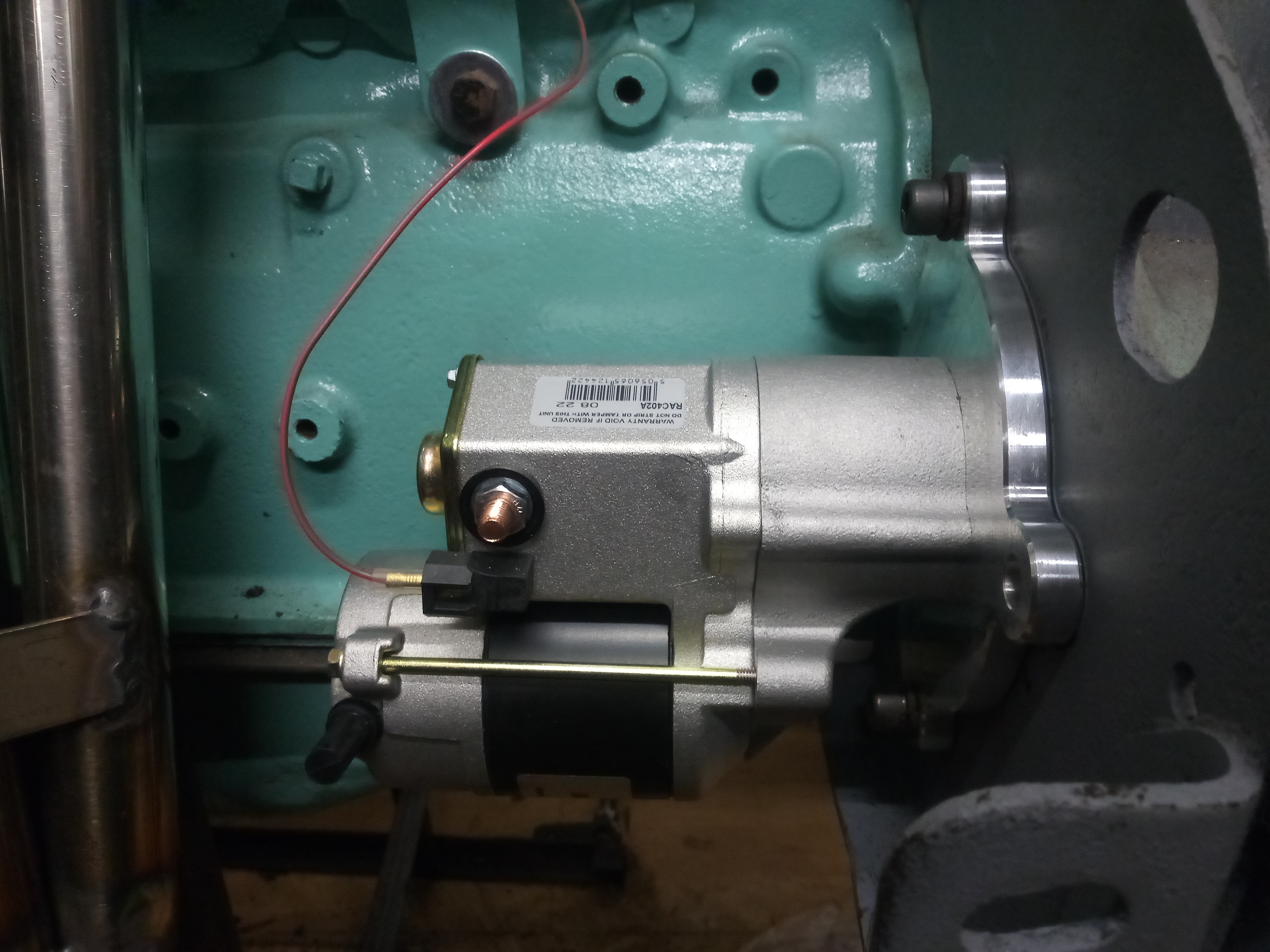

Snazzy new starter!

Marked improvement immediately! ...for all of one turn. My battery is

totally scrap at this point, I took it to work and used the

drop-tester and it went from 12.8 volts to "just take it out behind

the shed and shoot it" instantly. Ah well, it's just more money.

Replacement spigot bearing

Yup, it's definitely our good old friend the skateboard wheel bearing, but I got a genuine SKF one so that should do nicely.

Rocker cover hold-downs! (Almost)

I should've gotten bigger washers... Also, not shown -- because I've not made them yet -- is that I'm going to make up some leather washers that go underneath the (replacements for the) pictured washers, that will act as a seal and a bit of compliance.

I screwed up getting new belts

1090 is too short with an alternator! So I got... drumroll one that

was 50mm shorter still.  This is why I write things down, otherwise I am guaranteed to forget

measurements. Thankfully, they're not expensive, and I needed to order

belts for the compressor anyway so I just added replacements onto that

order. Anyone need a pair of 1040mm long B profile V belts?

This is why I write things down, otherwise I am guaranteed to forget

measurements. Thankfully, they're not expensive, and I needed to order

belts for the compressor anyway so I just added replacements onto that

order. Anyone need a pair of 1040mm long B profile V belts?

Aaaaaaaaalso, I still need to come up with a good replacement for the alternator pulley.

It being for car use, it's for an A profile V-belt (10mm wide) and has a 15mm shaft, but the vast majority of the pulleys I can find online for B profile have a 17mm centre bore; and the ones that aren't, seem to either have way too much offset, or are much larger so as to underdrive the alternator on a high-revving engine.

Seeing as the Bedford's 300 revs out in the region of 3300rpm and the alternator speed might be a bit marginal at idle, I may need to get myself a chunk of metal -- or maybe a blank-bore pulley with the right groove and a touch too much offset -- and spend some time on the lathe at work to come up with something appropriate.

Sealing

I'm trying out some ... potentially interesting techniques for making a couple of replacement gaskets, utilising EPDM rubber strip. A sheet of appropriately thick bonded-cork large enough to make a rocker cover gasket (and a 2nd thinner one to make an engine side-panel gasket from) is ... eyewateringly expensive. The rubber strip is significantly cheaper, and there's a lot less wasted material.

I shall keep you updated on how well that works out. (5mm thick for

the rocker cover, and 2mm thick for the engine side-panel. And I have

more than enough of each to repeat the process again if

necessary. There will be sealant involved in order to ensure

oil-tightness. Hoping to invoke the magic powers of Hondabond in order

to imbue my engine with the legendary oil-tightness of Japanese

engines. But it's entirely possible that it doesn't work, and I end up

with an engine that leaks more than a Gardner! Won't know unless I

try, though!