I've had a fairly productive week/long weekend so far, away from work (Which has been the land of gearbox/clutch hackery...)

The 26th

I got my new MIG torch in, so I celebrated by welding on my remaining two side-marker light brackets on the offside. Which, if my doctor's reading this, involved exactly 0 crawling or kneeling on the floor the day after having some exploratory work done on my knee. (Did you know they made needles 80mm long? Neither did I 'til then!)

One at the front

One at the front

And one at the back

And one at the back

Happy days!

Happy days!

The 28th

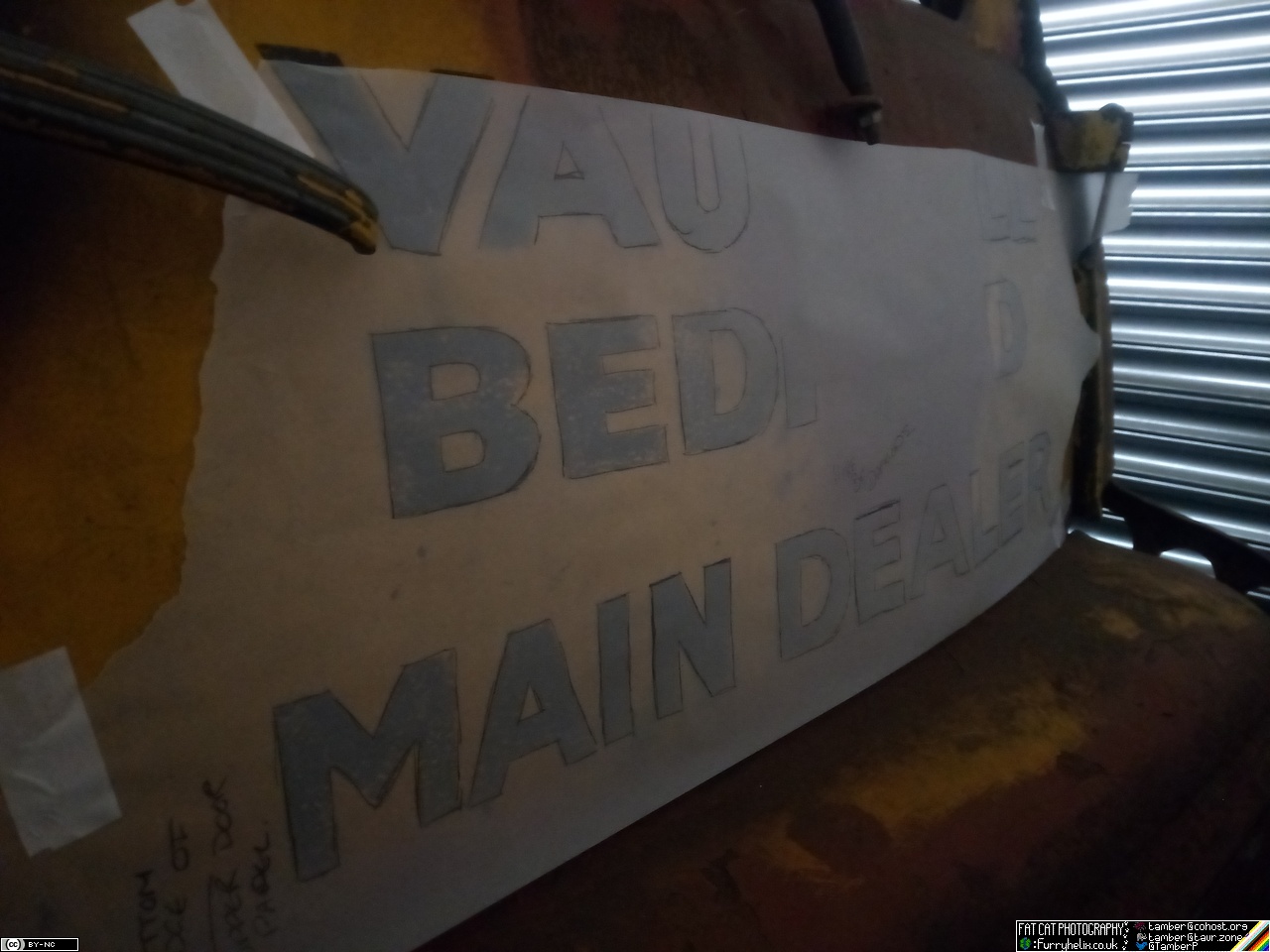

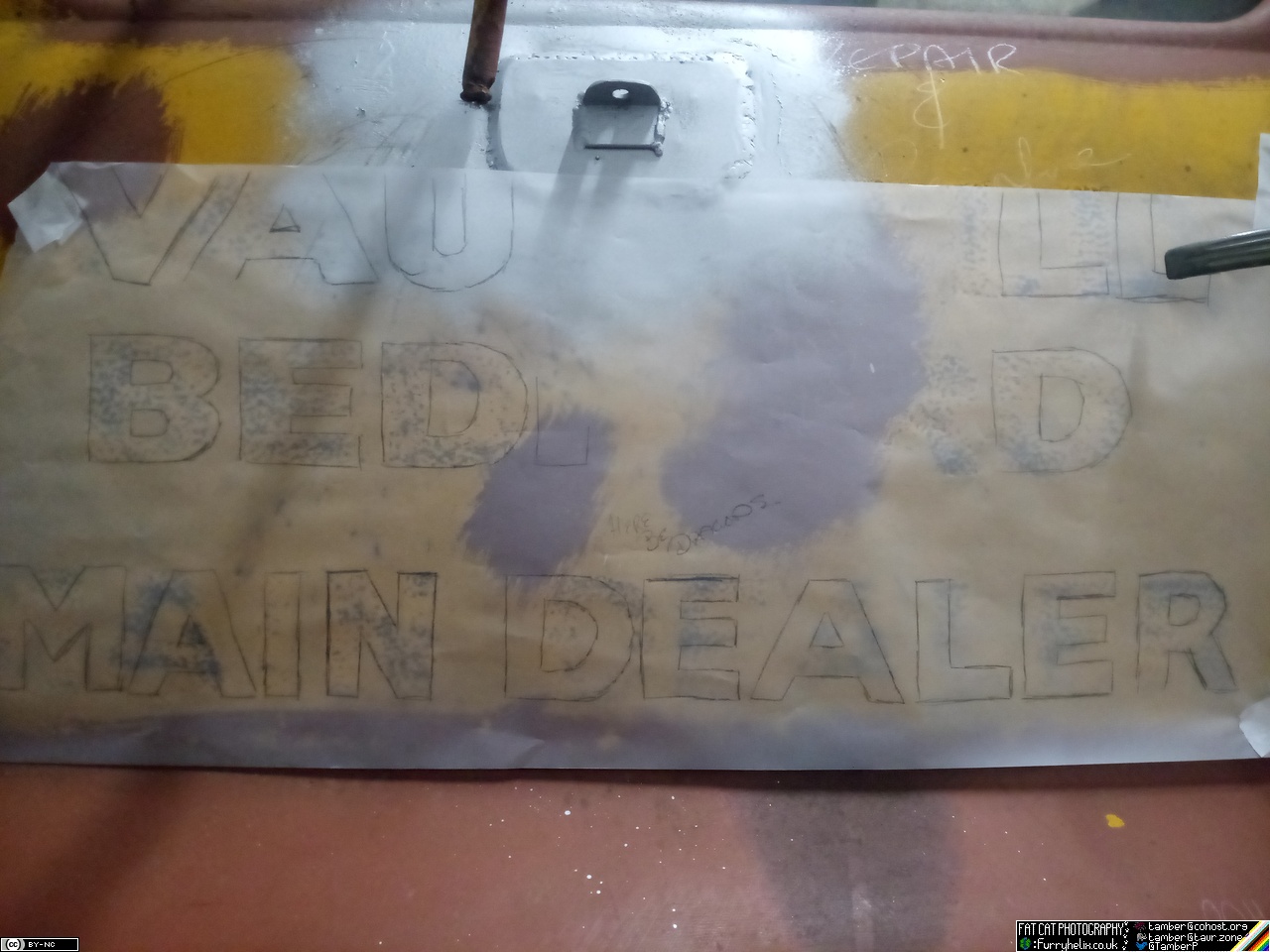

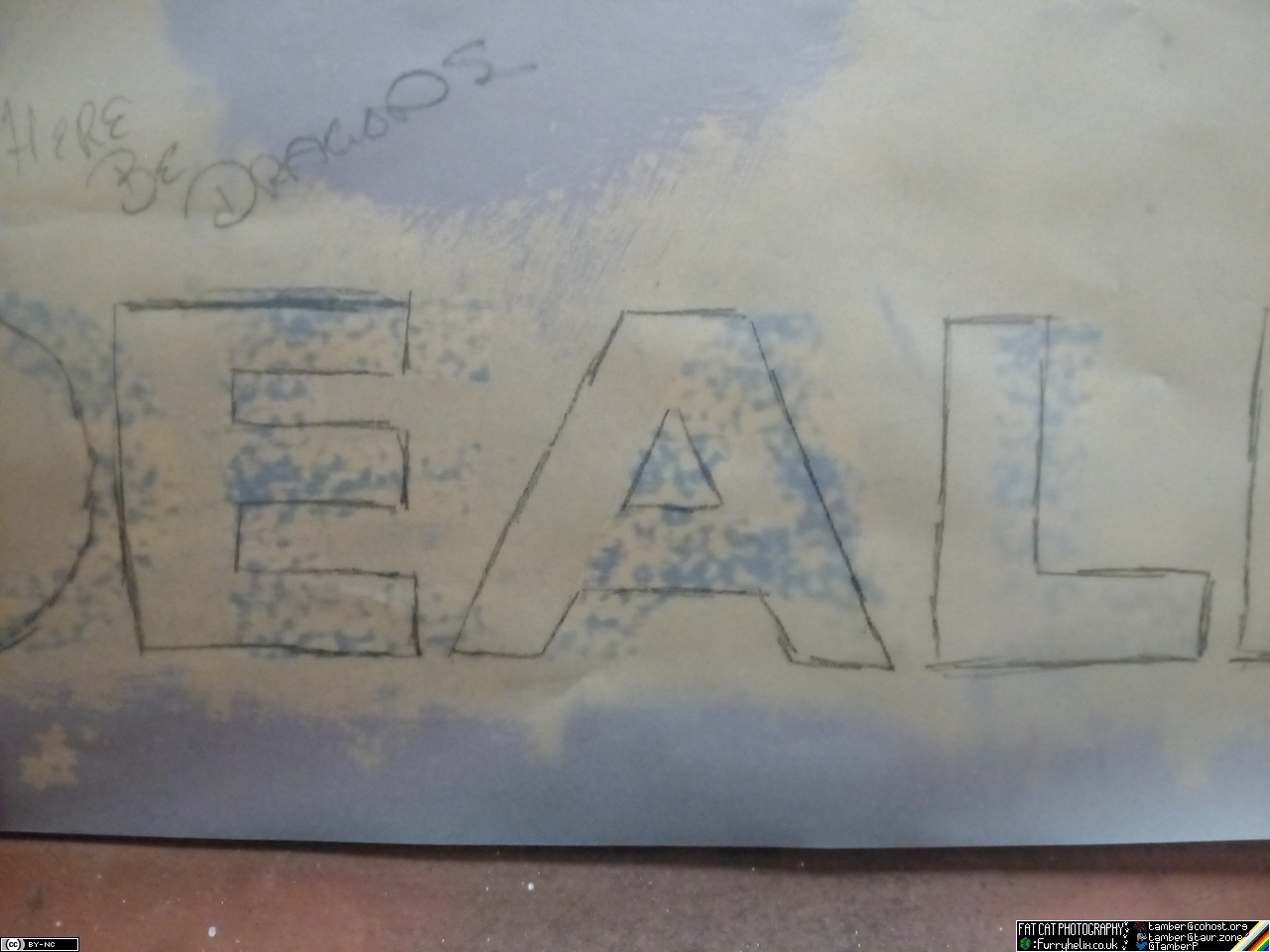

Got some tracing paper in, so I could take advantage of having put the truck too far away from the wall, and trace out the signwriting on the offside.

Well, what's left of it, in some cases.

See, I managed to wipe out the same bit on both doors before I managed to get a tracing of it. Thankfully, I have enough pictures that I can reassemble the missing bits pretty close to how it used to be; they won't be exactly identical, because I'm probably going to move the "vauxhall" and "bedford" bits down to miss the mirror bracket, but...

...that's alright, because they weren't identical to begin with. :D

I did also make a set of tracings of the "Scott Bros. (Colchester) Ltd" on the locker doors, but no pictures of that because it was incredibly close-quarters in there!

The 29th

Dragged the locker out from the nearside, and stripped all the old mud, underseal, and paint. It's in pretty good condition underneath, all things considered. Much better than the locker in front of it.

Dragged the locker out from the nearside, and stripped all the old mud, underseal, and paint. It's in pretty good condition underneath, all things considered. Much better than the locker in front of it.

A nice heavy couple of coats of primer...

A nice heavy couple of coats of primer...

The 31st

Not a lot of pictures from today, because my phone was on music duties again. I did interrupt it in order to grab a snapshot of the whole ridiculous mess that was reftting the locker. I should note, this was 2-1/2 hours into proceedings; I had to give every enclosed side of that locker a coat or two of black paint, which thankfully dried pretty quickly in the warm sunlight. And while it was drying, I made up a mounting bracket for my air manifolds. (Unpictured. I'll have to grab a snap next time I'm down there.)

I also went and tack-welded in the bolts at the forward end of the locker, because there's no way to get a spanner on them in order to prevent them spinning. I'm not entirely sure how they were originally put in, because there's a floor above them and they're inside a C section in such a way that you can't hold a spanner in from the side even if the forwardmost locker wasn't there!

This was round two of trying to fit it; the previous round, the bike

jack launched itself out as I tried to squeeze the locker into place

atop it, and I ended up making an attempt to fit the locker by lifting

it a bit at a time and blocking it up... only to find out I only

drilled the mounting holes to 8mm, and the mounting bolts are 3/8.

This was round two of trying to fit it; the previous round, the bike

jack launched itself out as I tried to squeeze the locker into place

atop it, and I ended up making an attempt to fit the locker by lifting

it a bit at a time and blocking it up... only to find out I only

drilled the mounting holes to 8mm, and the mounting bolts are 3/8.

Redrill holes, reassemble the whole silly stack. Discover that all the bumping and banging has tweaked two of the mounting bolts... Make up a special tool (bent stick) in order to reach in through the narrow gap and pull the bolts back into place, then pump the jack to shove the box over the bolts before anything else moves out of place! And, of course, this results in scraping off a non-zero amount of the paint I put on this morning.

...but most of it's still painted so that's something. The worst of the paint damage is on the underside, which I can still get to in order to repaint it.

Tada!

Tada!

I will, of course, have to clean and paint the inside of that; which promises to be fun. Oh, and strip & paint the face of it that has the door on, of course. But I might leave that 'til I've pulled the door off and repaired/re-made it, because it's suffered quite badly from The Rot.

Then, three hours of tin-bashing, heating & forming, welding,

grinding, more bashing... and we finally have the nearside-front rear

wing put back on!

It's only partially welded in place, the rest of it's just tacked for now, and I've just hosed over the welds with the zinc primer for ... I don't know why I did it, really, I'm only going to end up taking a bunch of it off when I grind them down. Makes me feel better, I guess? No it's not pretty. More work to do on it, which will neaten it up a good bit; but even then it will probably still show the scars of the repair, and I'm fine with that. :)

Still some bashing and fitting to do in order to close up gaps before fully welding, but it's on now which is good news for multiple reasons:

- It's not floating around for me to trip over and damage

- Another piece goes back onto the truck!

- It's been holding up figuring out where I can put the compressor's air supply and unloader return pipes. So now I can make the bracketry to fit those! (Just in time for me to run out of gas for the TIG welder, I'm sure.)